Technology

Learn about the platform powering today's most advanced automation applications

Technology

Learn about the platform powering today's most advanced automation applications

Precision Piece Picking: Fast, Reliable, and Designed for Today’s SKU Explosion

Precision Piece Picking: Fast, Reliable, and Designed for Today’s SKU Explosion

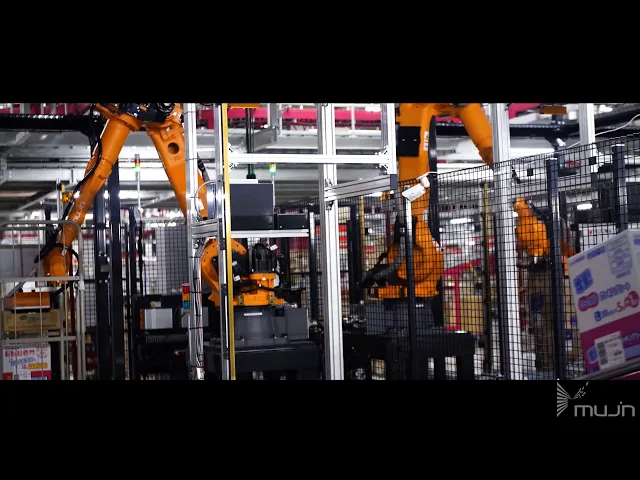

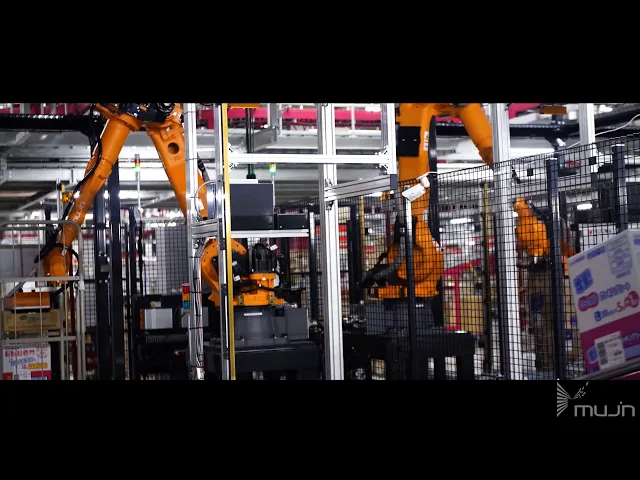

In e‑commerce and many other warehouse environments, piece picking is one of the most labor‑intensive and critical functions, requiring precise handling of diverse products. Mujin’s piece‑picking systems automate this complexity, ensuring efficient, reliable fulfillment even as order volumes and SKU counts continue to grow.

In e‑commerce and many other warehouse environments, piece picking is one of the most labor‑intensive and critical functions, requiring precise handling of diverse products. Mujin’s piece‑picking systems automate this complexity, ensuring efficient, reliable fulfillment even as order volumes and SKU counts continue to grow.

In e‑commerce and many other warehouse environments, piece picking is one of the most labor‑intensive and critical functions, requiring precise handling of diverse products. Mujin’s piece‑picking systems automate this complexity, ensuring efficient, reliable fulfillment even as order volumes and SKU counts continue to grow.

Unmatched Item Handling Flexibility

Unmatched Item Handling Flexibility

Mujin’s piece-picking system tackles extreme SKU variety using high-speed tool changing that lets robots switch between grippers instantly. Mega Suction and multipad grippers allow reliable handling of everything from soft apparel to irregular or hard-to-grip items. This flexibility solves the e-commerce “pieces problem,” enabling fulfillment centers to keep pace with large-scale, fast-growing order volumes.

Mujin’s piece-picking system tackles extreme SKU variety using high-speed tool changing that lets robots switch between grippers instantly. Mega Suction and multipad grippers allow reliable handling of everything from soft apparel to irregular or hard-to-grip items. This flexibility solves the e-commerce “pieces problem,” enabling fulfillment centers to keep pace with large-scale, fast-growing order volumes.

To embed a Youtube video, add the URL to the properties panel.

To embed a Youtube video, add the URL to the properties panel.

To embed a Youtube video, add the URL to the properties panel.

Higher Accuracy Through Intelligent Inspection and Damage-Free Handling

Higher Accuracy Through Intelligent Inspection and Damage-Free Handling

Each picked item is automatically inspected with a code reader, ensuring accurate code verification, significantly reducing shipping errors. Independently controlled suction pads preserve product quality while maintaining strong, secure gripping. Continuous 3D vision monitoring prevents damage inside containers and maintains high loading efficiency with minimal wasted motion.

Each picked item is automatically inspected with a code reader, ensuring accurate code verification, significantly reducing shipping errors. Independently controlled suction pads preserve product quality while maintaining strong, secure gripping. Continuous 3D vision monitoring prevents damage inside containers and maintains high loading efficiency with minimal wasted motion.

Scalable Automation That Reduces Labor Burden and Boosts Throughput

Scalable Automation That Reduces Labor Burden and Boosts Throughput

Mujin’s high-speed piece-picking robots automate 60–70% of logistics center work traditionally dependent on scarce labor. By taking on repetitive pick-and-place tasks, they improve throughput while freeing workers from routine roles they increasingly avoid. The system integrates seamlessly with upstream unloading and downstream palletizing, creating an end-to-end automation flow that ensures accurate, reliable fulfillment at scale.

Mujin’s high-speed piece-picking robots automate 60–70% of logistics center work traditionally dependent on scarce labor. By taking on repetitive pick-and-place tasks, they improve throughput while freeing workers from routine roles they increasingly avoid. The system integrates seamlessly with upstream unloading and downstream palletizing, creating an end-to-end automation flow that ensures accurate, reliable fulfillment at scale.

Robotic Picking Built for Warehouse Complexity

Robotic Picking Built for Warehouse Complexity

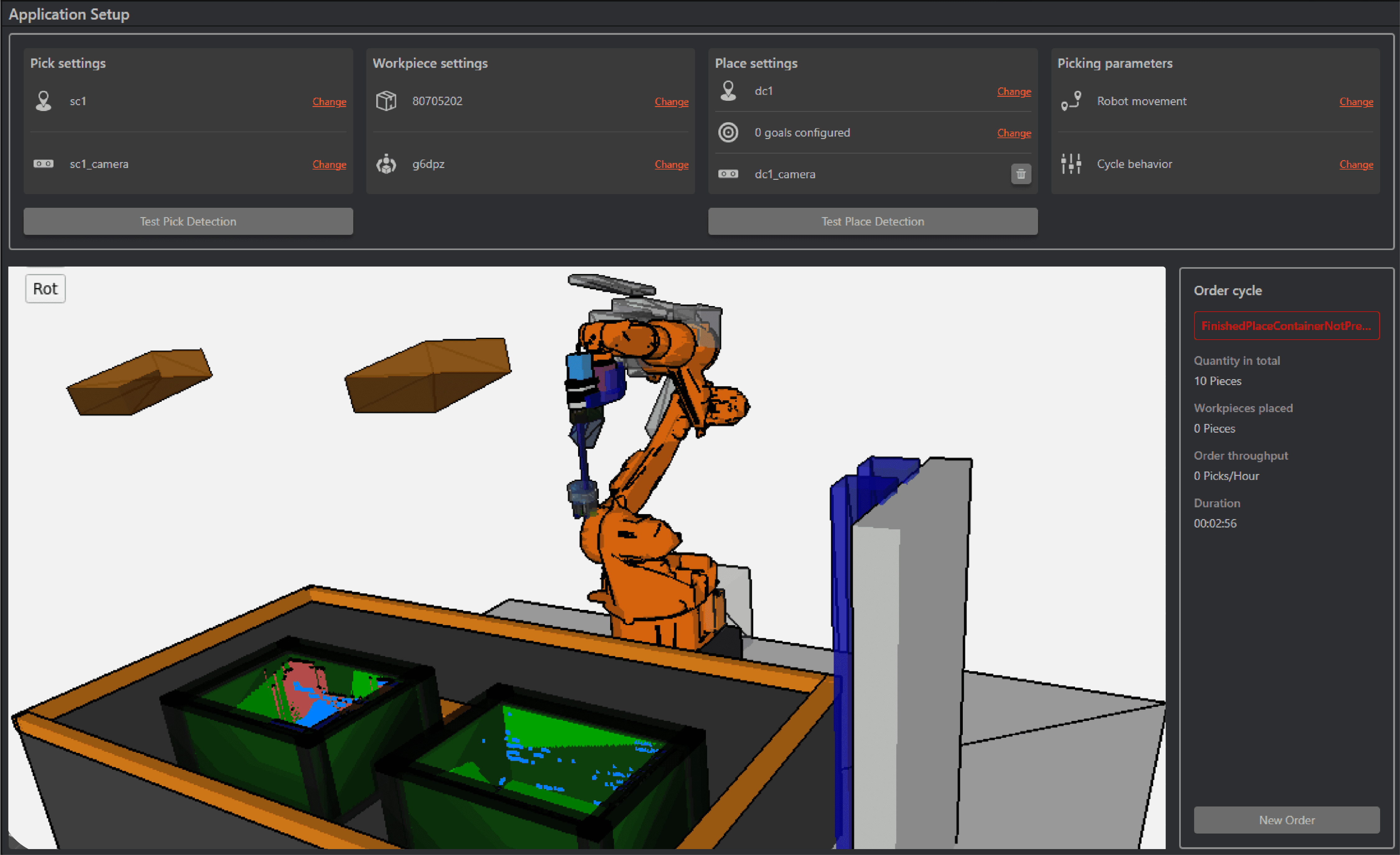

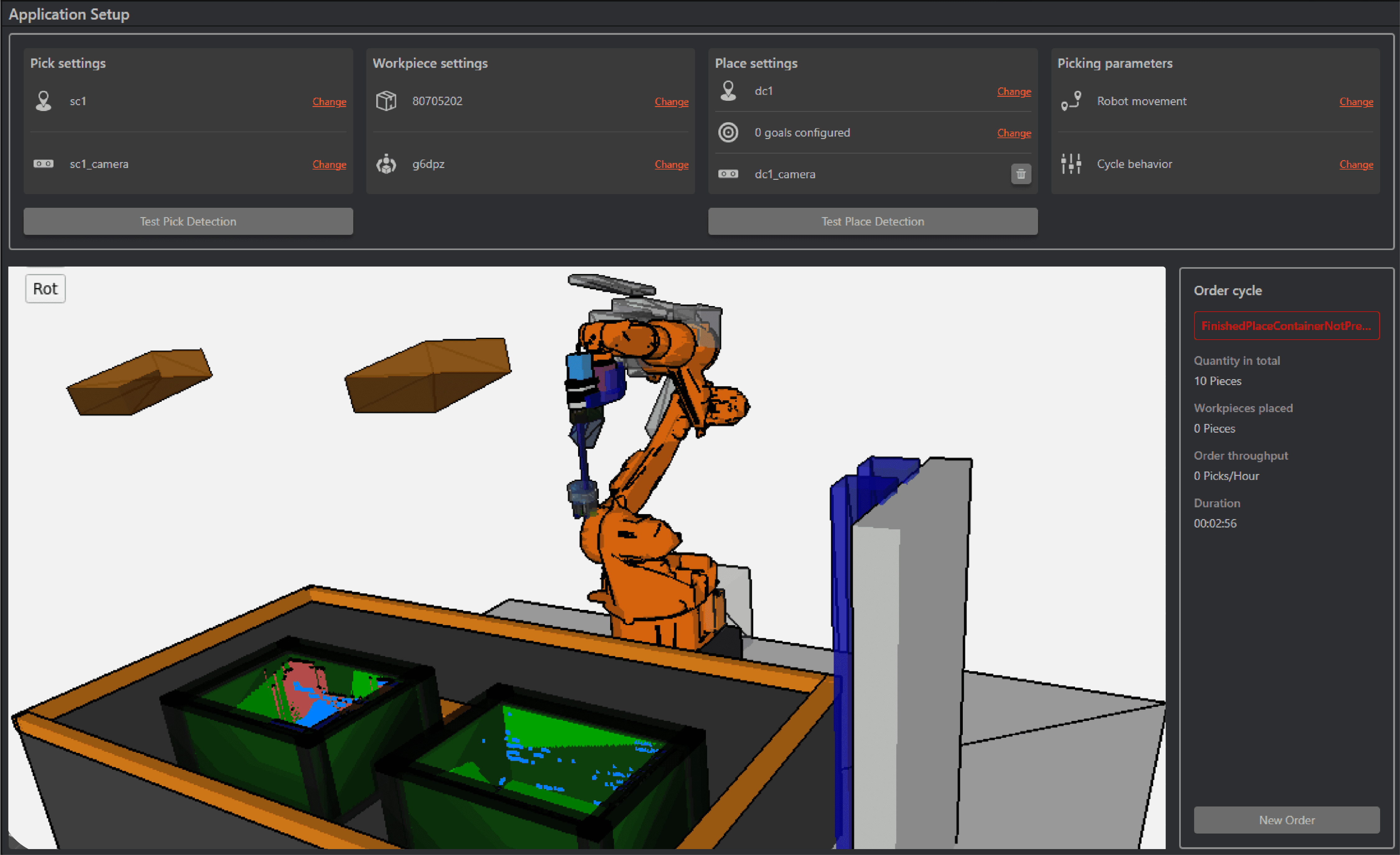

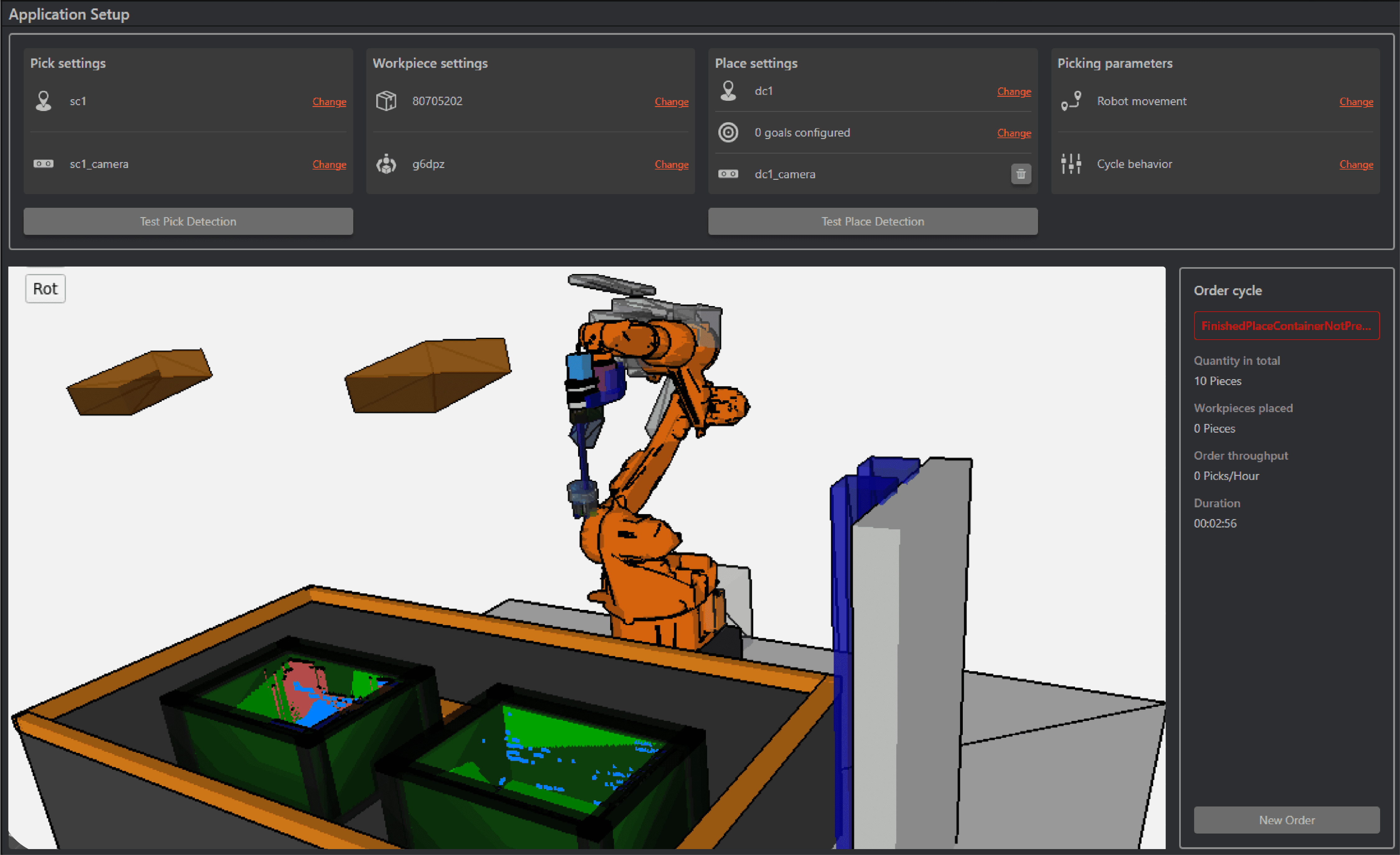

Piece picking has long been a bottleneck in warehouse automation. MujinOS eliminates manual teaching and constant tuning, unifying perception, grasping, and motion control into one teachless, software-defined workflow. The result: accurate, consistent picking across random bins, variable SKUs, and real-world packaging — with sustained throughput and minimal downtime.

Piece picking has long been a bottleneck in warehouse automation. MujinOS eliminates manual teaching and constant tuning, unifying perception, grasping, and motion control into one teachless, software-defined workflow. The result: accurate, consistent picking across random bins, variable SKUs, and real-world packaging — with sustained throughput and minimal downtime.

Random Inventory

Items arrive unsorted and shift constantly, breaking rule-based bin picking. MujinOS adapts in real time to pick reliably from random bins and totes.

Random Inventory

Items arrive unsorted and shift constantly, breaking rule-based bin picking. MujinOS adapts in real time to pick reliably from random bins and totes.

Random Inventory

Items arrive unsorted and shift constantly, breaking rule-based bin picking. MujinOS adapts in real time to pick reliably from random bins and totes.

SKU Variability

Thousands of SKUs and changing packaging require manual teaching. MujinOS enables teachless bin picking that adapts automatically.

SKU Variability

Thousands of SKUs and changing packaging require manual teaching. MujinOS enables teachless bin picking that adapts automatically.

SKU Variability

Thousands of SKUs and changing packaging require manual teaching. MujinOS enables teachless bin picking that adapts automatically.

Throughput Instability

Accuracy drops and downtime increase as conditions change. Unified control maintains consistent pick rates at scale.

Throughput Instability

Accuracy drops and downtime increase as conditions change. Unified control maintains consistent pick rates at scale.

Throughput Instability

Accuracy drops and downtime increase as conditions change. Unified control maintains consistent pick rates at scale.

Scaling Limits

Custom cells are hard to replicate across sites and workflows. A common software layer scales bin picking without reengineering.

Scaling Limits

Custom cells are hard to replicate across sites and workflows. A common software layer scales bin picking without reengineering.

Scaling Limits

Custom cells are hard to replicate across sites and workflows. A common software layer scales bin picking without reengineering.

Making Robotic Piece Picking a Reality.

How MujinOS makes robotic piece picking a reality

Teachless Intelligence

Configure new SKUs or bins in minutes. MujinOS automates pick zone definition, grasp logic, and trajectory generation — no robot teaching or coding required

Seamless Changeovers

Continuous 3D vision and sensor feedback enable adaptive grasp and motion decisions — maintaining accuracy as items, lighting, or bin positions change

Platform Integration

Seamlessly connects to WMS, WES, ASRS, and AMRs for synchronized material flow — making piece picking part of a fully automated warehouse system

Teachless Intelligence

Configure new SKUs or bins in minutes. MujinOS automates pick zone definition, grasp logic, and trajectory generation — no robot teaching or coding required

Making Robotic Piece Picking a Reality.

How MujinOS makes robotic piece picking a reality

Teachless Intelligence

Configure new SKUs or bins in minutes. MujinOS automates pick zone definition, grasp logic, and trajectory generation — no robot teaching or coding required

Seamless Changeovers

Continuous 3D vision and sensor feedback enable adaptive grasp and motion decisions — maintaining accuracy as items, lighting, or bin positions change

Platform Integration

Seamlessly connects to WMS, WES, ASRS, and AMRs for synchronized material flow — making piece picking part of a fully automated warehouse system

Teachless Intelligence

Configure new SKUs or bins in minutes. MujinOS automates pick zone definition, grasp logic, and trajectory generation — no robot teaching or coding required

Making Robotic Piece Picking a Reality.

How MujinOS makes robotic piece picking a reality

Teachless Intelligence

Configure new SKUs or bins in minutes. MujinOS automates pick zone definition, grasp logic, and trajectory generation — no robot teaching or coding required

Seamless Changeovers

Continuous 3D vision and sensor feedback enable adaptive grasp and motion decisions — maintaining accuracy as items, lighting, or bin positions change

Platform Integration

Seamlessly connects to WMS, WES, ASRS, and AMRs for synchronized material flow — making piece picking part of a fully automated warehouse system

Teachless Intelligence

Configure new SKUs or bins in minutes. MujinOS automates pick zone definition, grasp logic, and trajectory generation — no robot teaching or coding required

Easy setup

Easy setup

See how leading integrators are scaling faster and winning more business with MujinOS. From warehouse logistics to automotive assembly, these deployments show how MujinOS simplifies complex automation—turning one-off projects into repeatable solutions.

See how leading integrators are scaling faster and winning more business with MujinOS. From warehouse logistics to automotive assembly, these deployments show how MujinOS simplifies complex automation—turning one-off projects into repeatable solutions.

Case study

See intelligent picking in production at FANCL

MujinOS-enabled robots are transforming manual each-picking into scalable automation — delivering consistent, accurate picks across millions of SKUs for leading global retailers and logistics providers.

Case study

See intelligent picking in production at FANCL

MujinOS-enabled robots are transforming manual each-picking into scalable automation — delivering consistent, accurate picks across millions of SKUs for leading global retailers and logistics providers.

Case study

See intelligent picking in production at FANCL

MujinOS-enabled robots are transforming manual each-picking into scalable automation — delivering consistent, accurate picks across millions of SKUs for leading global retailers and logistics providers.

Download the MujinOS brochure

Download the MujinOS brochure

This technical guide explains how MujinOS eliminates reprogramming, accelerates changeovers, and delivers consistent high performance across palletizing applications. It’s packed with practical insights for operations leaders, engineers, and integrators evaluating automated palletizing systems.

Let’s automate what others can’t

Talk to our experts to see how MujinOS can make your piece picking operations faster, simpler, and more reliable

Let’s automate what others can’t

Talk to our experts to see how MujinOS can make your piece picking operations faster, simpler, and more reliable

Let’s automate what others can’t

Talk to our experts to see how MujinOS can make your piece picking operations faster, simpler, and more reliable