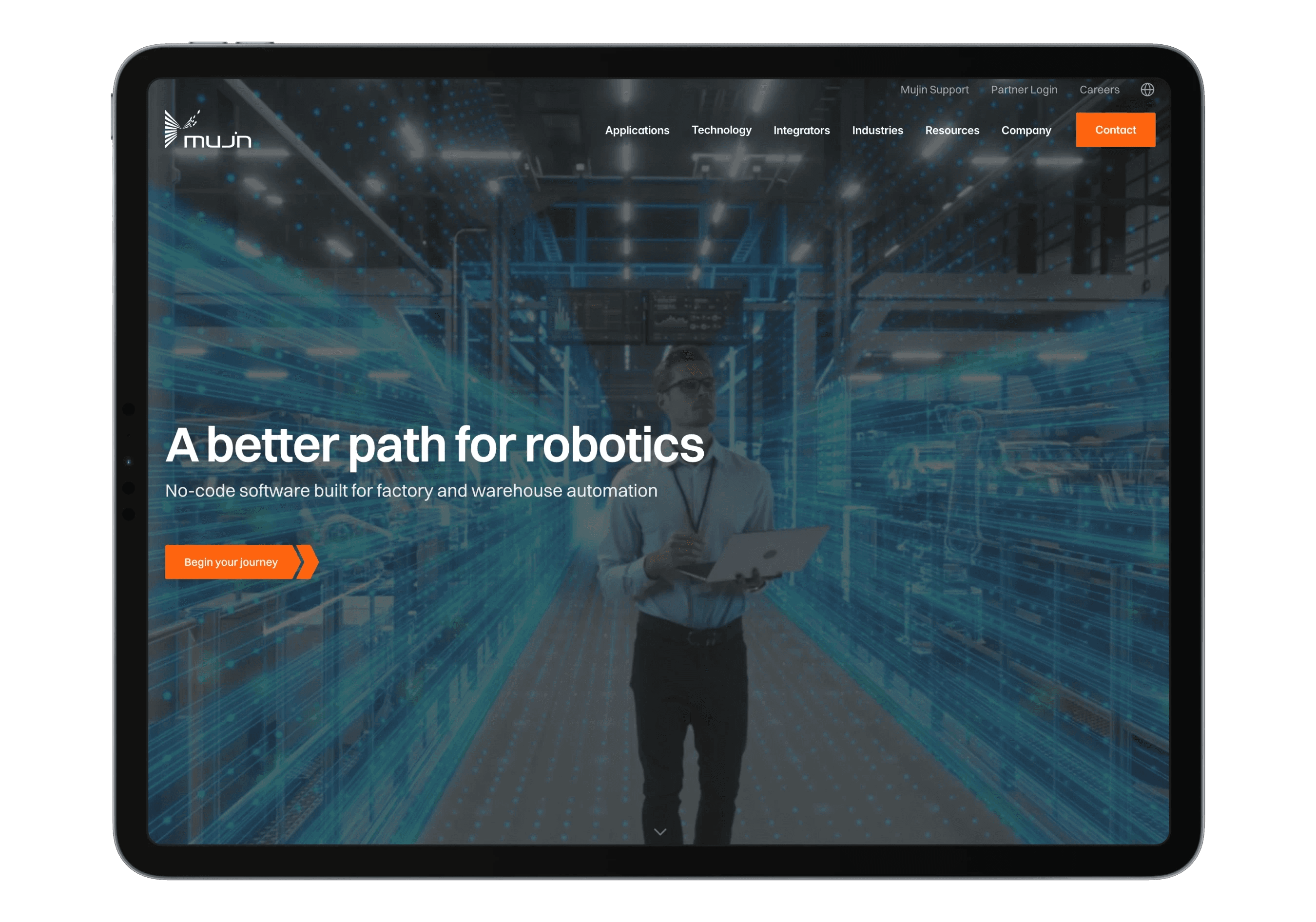

Technology

Learn about the platform powering today's most advanced automation applications

Technology

Learn about the platform powering today's most advanced automation applications

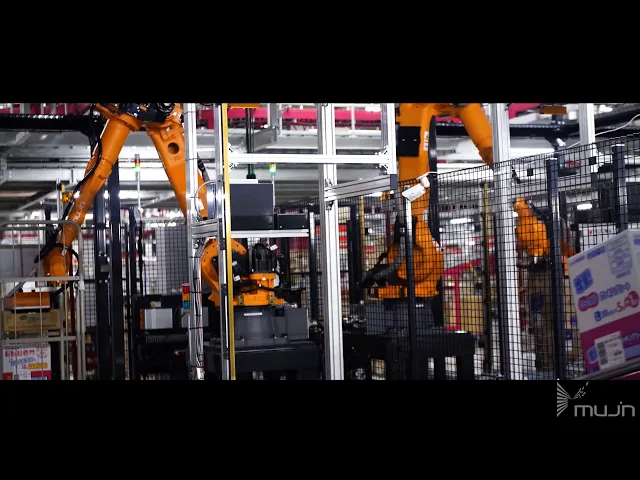

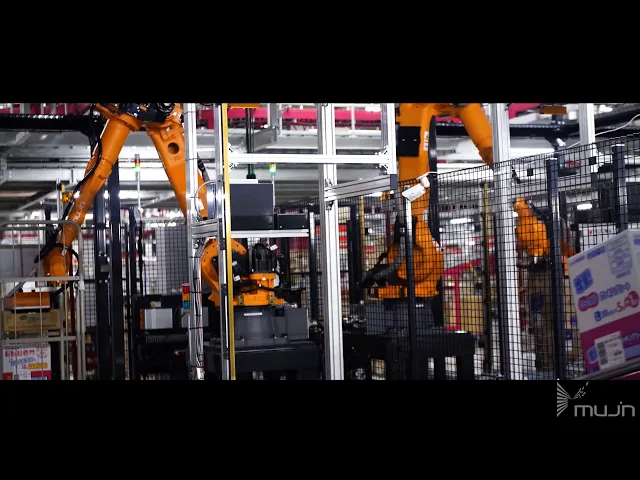

AI-Driven Palletizing for High-Mix, High-Throughput Operations

AI-Driven Palletizing for High-Mix, High-Throughput Operations

Intelligent palletizing that adapts to SKU variability, changing demand, and real-world constraints without reprogramming

Intelligent palletizing that adapts to SKU variability, changing demand, and real-world constraints without reprogramming

Intelligent palletizing that adapts to SKU variability, changing demand, and real-world constraints without reprogramming

Physical AI that outperforms traditional palletizing at every level

Physical AI that outperforms traditional palletizing at every level

Our system removes the need for hand tuned- pallet patterns or manual robot programming. It evaluates case size, weight balance, and stability on the fly to automatically generate the most stable and efficient pallet configurations.

Our system removes the need for hand tuned- pallet patterns or manual robot programming. It evaluates case size, weight balance, and stability on the fly to automatically generate the most stable and efficient pallet configurations.

To embed a Youtube video, add the URL to the properties panel.

To embed a Youtube video, add the URL to the properties panel.

To embed a Youtube video, add the URL to the properties panel.

See MujinOS make better decisions in real time

See MujinOS make better decisions in real time

Our system uses a live digital twin to understand what has arrived, what’s coming next and how to build pallets most efficiently adjusting continuously without stopping operations.

Our system uses a live digital twin to understand what has arrived, what’s coming next and how to build pallets most efficiently adjusting continuously without stopping operations.

Adaptive Intelligence for Fast, Real-World- Palletizing

Adaptive Intelligence for Fast, Real-World- Palletizing

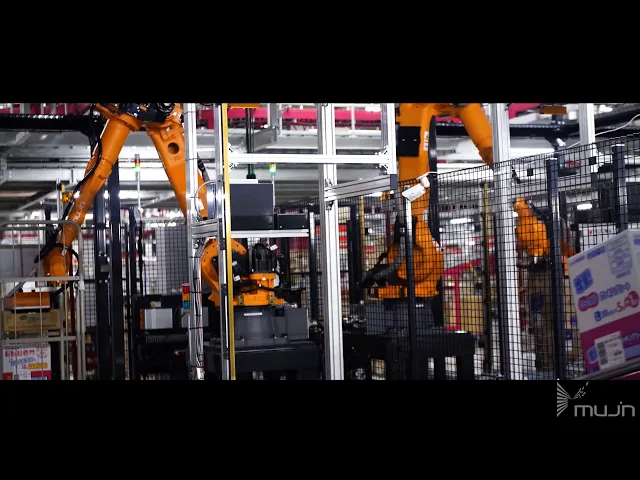

MujinOS is the intelligence layer that drives high speed, autonomous inbound palletizing at scale. Designed for maximum throughput, the system consistently delivers industry- leading performance—exceeding- 1,000 cases per hour—even when handling variable SKUs and multipick- operations.

MujinOS is the intelligence layer that drives high speed, autonomous inbound palletizing at scale. Designed for maximum throughput, the system consistently delivers industry- leading performance—exceeding- 1,000 cases per hour—even when handling variable SKUs and multipick- operations.

Physical AI that boosts capability and reduces complexity

Physical AI that boosts capability and reduces complexity

With MujinOS handling perception, pattern decisions, and motion planning, palletizing gains capabilities that traditional systems simply can’t deliver, all while keeping the system simple to operate.

With MujinOS handling perception, pattern decisions, and motion planning, palletizing gains capabilities that traditional systems simply can’t deliver, all while keeping the system simple to operate.

Adaptive Box Handling

Handles variation automatically with consistent, stable placement across package types.

Adaptive Box Handling

Handles variation automatically with consistent, stable placement across package types.

Adaptive Box Handling

Handles variation automatically with consistent, stable placement across package types.

Automated Pack Generation

Creates and validates optimized patterns in seconds for fast, reliable stack builds.

Automated Pack Generation

Creates and validates optimized patterns in seconds for fast, reliable stack builds.

Automated Pack Generation

Creates and validates optimized patterns in seconds for fast, reliable stack builds.

Intelligent Picking

Identifies multi-pick opportunities to increase throughput without added complexity.

Intelligent Picking

Identifies multi-pick opportunities to increase throughput without added complexity.

Intelligent Picking

Identifies multi-pick opportunities to increase throughput without added complexity.

Resilient Operation

Recovers from interruptions autonomously to keep production running across shifts.

Resilient Operation

Recovers from interruptions autonomously to keep production running across shifts.

Resilient Operation

Recovers from interruptions autonomously to keep production running across shifts.

Built on MujinOS

Engineered to optimize palletizing across both predictable and highly variable SKU environments

Single SKU

Multi SKU

Single-SKU Workflows

Optimized performance for steady, high-volume lines

Seamless Changeovers

Advanced motion planning keeps cases moving predictably across every shift

Instant Changeovers

Switch between patterns or SKUs in seconds with no reprogramming or engineering time

Operator-Friendly Control

Clear WebUI, guided recovery, and simple operation reduce training and supervision needs

Fast Pattern Setup

Create and validate new pallet patterns in under a minute, directly from the interface

Reliable, Shift-Ready Operation

Automated error handling and recovery help maintain uninterrupted performance

Built on MujinOS

Engineered to optimize palletizing across both predictable and highly variable SKU environments

Single SKU

Multi SKU

Single-SKU Workflows

Optimized performance for steady, high-volume lines

Seamless Changeovers

Advanced motion planning keeps cases moving predictably across every shift

Instant Changeovers

Switch between patterns or SKUs in seconds with no reprogramming or engineering time

Operator-Friendly Control

Clear WebUI, guided recovery, and simple operation reduce training and supervision needs

Fast Pattern Setup

Create and validate new pallet patterns in under a minute, directly from the interface

Reliable, Shift-Ready Operation

Automated error handling and recovery help maintain uninterrupted performance

Built on MujinOS

Engineered to optimize palletizing across both predictable and highly variable SKU environments

Single SKU

Multi SKU

Single-SKU Workflows

Optimized performance for steady, high-volume lines

Seamless Changeovers

Advanced motion planning keeps cases moving predictably across every shift

Instant Changeovers

Switch between patterns or SKUs in seconds with no reprogramming or engineering time

Operator-Friendly Control

Clear WebUI, guided recovery, and simple operation reduce training and supervision needs

Fast Pattern Setup

Create and validate new pallet patterns in under a minute, directly from the interface

Reliable, Shift-Ready Operation

Automated error handling and recovery help maintain uninterrupted performance

Easy setup

Easy setup

See how leading integrators are scaling faster and winning more business with MujinOS. From warehouse logistics to automotive assembly, these deployments show how MujinOS simplifies complex automation—turning one-off projects into repeatable solutions.

See how leading integrators are scaling faster and winning more business with MujinOS. From warehouse logistics to automotive assembly, these deployments show how MujinOS simplifies complex automation—turning one-off projects into repeatable solutions.

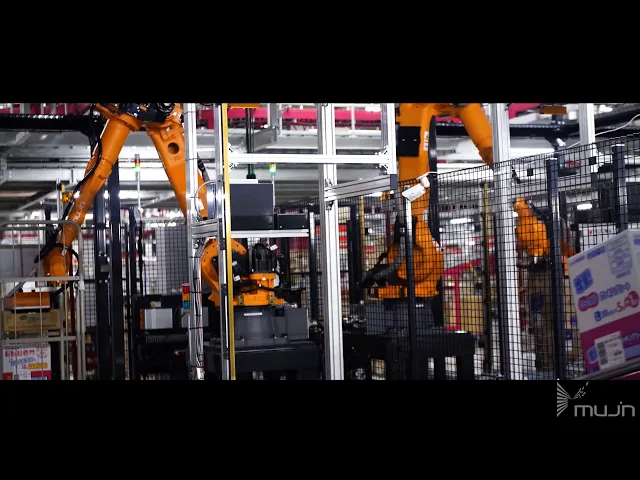

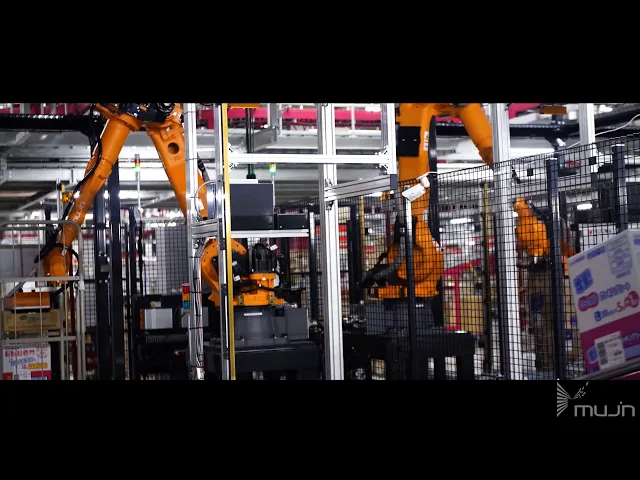

Case study

See intelligent robots palletize at PALTAC

MujinOS helped PALTAC open a new generation of logistics centers by transforming manual case packing into an automated palletizing system that can work with pallets, cages and carts.

Case study

See intelligent robots palletize at PALTAC

MujinOS helped PALTAC open a new generation of logistics centers by transforming manual case packing into an automated palletizing system that can work with pallets, cages and carts.

Case study

See intelligent robots palletize at PALTAC

MujinOS helped PALTAC open a new generation of logistics centers by transforming manual case packing into an automated palletizing system that can work with pallets, cages and carts.

Download the MujinOS brochure

Download the MujinOS brochure

This technical guide explains how MujinOS eliminates reprogramming, accelerates changeovers, and delivers consistent high performance across palletizing applications. It’s packed with practical insights for operations leaders, engineers, and integrators evaluating automated palletizing systems.

Have a question?

Learn how MujinOS delivers real-time perception, motion control, and no-code deployment—across any robotic system

Have a question?

Learn how MujinOS delivers real-time perception, motion control, and no-code deployment—across any robotic system

Have a question?

Learn how MujinOS delivers real-time perception, motion control, and no-code deployment—across any robotic system