Technology

Learn about the platform powering today's most advanced automation applications

Technology

Learn about the platform powering today's most advanced automation applications

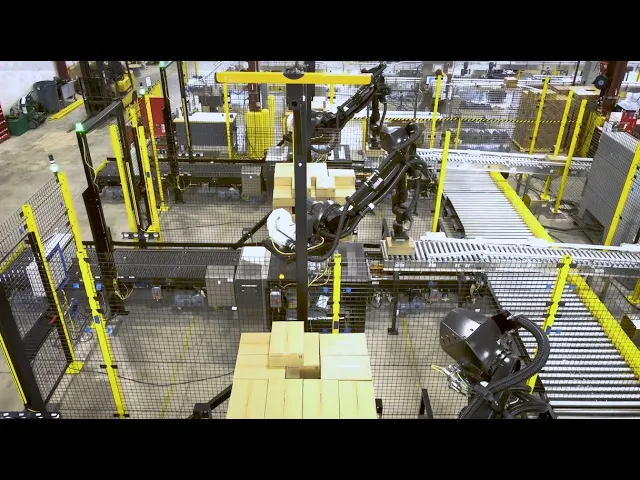

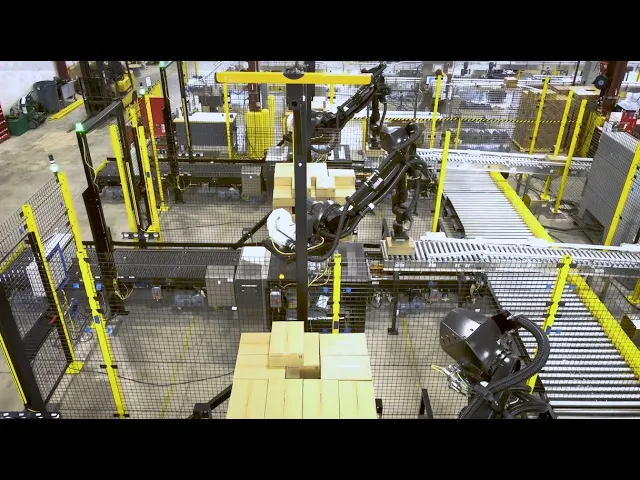

Robotic Depalletizing for Dynamic, Multi‑SKU Inbound Workflows

Robotic Depalletizing for Dynamic, Multi‑SKU Inbound Workflows

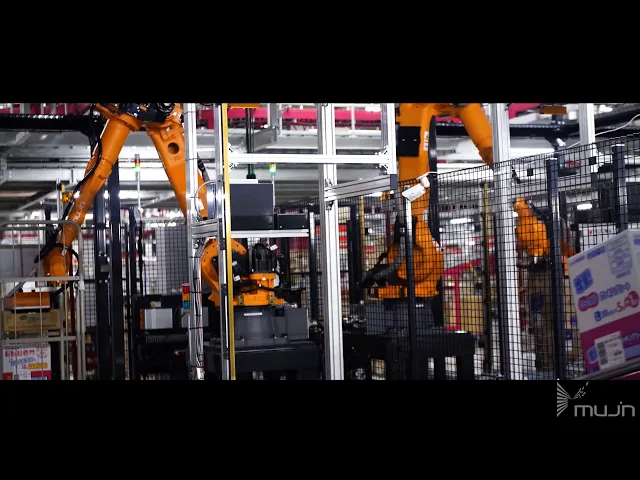

Robotic depalletizing is the critical induction point of automated warehouse operations, requiring precise handling of mixed and unpredictable pallet loads. Mujin’s advanced platform delivers the vision, control, and adaptability needed to execute high‑throughput depalletizing with exceptional reliability.

Robotic depalletizing is the critical induction point of automated warehouse operations, requiring precise handling of mixed and unpredictable pallet loads. Mujin’s advanced platform delivers the vision, control, and adaptability needed to execute high‑throughput depalletizing with exceptional reliability.

Robotic depalletizing is the critical induction point of automated warehouse operations, requiring precise handling of mixed and unpredictable pallet loads. Mujin’s advanced platform delivers the vision, control, and adaptability needed to execute high‑throughput depalletizing with exceptional reliability.

Software-Defined Robotic Depalletizing

Software-Defined Robotic Depalletizing

MujinOS enables teachless depalletizing that adapts to mixed SKUs, variable pallet patterns, and real-world packaging—maintaining high throughput with minimal downtime

MujinOS enables teachless depalletizing that adapts to mixed SKUs, variable pallet patterns, and real-world packaging—maintaining high throughput with minimal downtime

Scaling Depalletizing Automation

Scaling Depalletizing Automation

Custom depalletizing cells limit expansion—MujinOS provides a common software layer that scales depalletizing across sites and workflows without reengineering

Custom depalletizing cells limit expansion—MujinOS provides a common software layer that scales depalletizing across sites and workflows without reengineering

High-performance automation that manages uncertainty

High-performance automation that manages uncertainty

MujinOS brings predictability to unpredictable environments. By combining real-time 3D vision, adaptive motion control, and teachless configuration, it enables robots to handle irregular pallets, mixed-SKU loads, and damaged packaging with consistent precision — keeping operations moving, even when the inputs aren’t perfect.

MujinOS brings predictability to unpredictable environments. By combining real-time 3D vision, adaptive motion control, and teachless configuration, it enables robots to handle irregular pallets, mixed-SKU loads, and damaged packaging with consistent precision — keeping operations moving, even when the inputs aren’t perfect.

Unstable Single-SKU Pallets

AI-driven depalletizing adapts to shifted and deformed single-SKU loads without manual retuning.

Unstable Single-SKU Pallets

AI-driven depalletizing adapts to shifted and deformed single-SKU loads without manual retuning.

Unstable Single-SKU Pallets

AI-driven depalletizing adapts to shifted and deformed single-SKU loads without manual retuning.

Labor-Intensive Work

Teachless depalletizing automation reduces labor dependency while improving safety and uptime.

Labor-Intensive Work

Teachless depalletizing automation reduces labor dependency while improving safety and uptime.

Labor-Intensive Work

Teachless depalletizing automation reduces labor dependency while improving safety and uptime.

Inbound Bottlenecks

Unified AI control maintains consistent depalletizing throughput across changing inbound volumes.

Inbound Bottlenecks

Unified AI control maintains consistent depalletizing throughput across changing inbound volumes.

Inbound Bottlenecks

Unified AI control maintains consistent depalletizing throughput across changing inbound volumes.

Packaging Variability

AI-driven depalletizing adapts to changing case sizes and packaging without retuning.

Packaging Variability

AI-driven depalletizing adapts to changing case sizes and packaging without retuning.

Packaging Variability

AI-driven depalletizing adapts to changing case sizes and packaging without retuning.

Making Robotic Piece Picking a Reality

Unlock intelligent capabilities for both single-SKU and mixed-SKU depalletizing

Single SKU

Multi SKU

High Throughput

Optimized motion paths and cycle planning deliver fast, consistent case-per-minute performance on uniform pallets

Seamless Changeovers

Handles dropped, misaligned, or damaged cases automatically — no stoppages, no operator resets

Compact Integration

Fits easily into existing inbound lines with minimal floor-space impact or workflow disruption

Operator Simplicity

Visual WebUI and guided tools make configuration and monitoring intuitive for every skill level

Vision-Guided Accuracy

3D perception identifies each case precisely, even under shrink-wrap or variable lighting

Proven Reliability

Designed for continuous operation across shifts, with autonomous fault handling and status reporting

Making Robotic Piece Picking a Reality

Unlock intelligent capabilities for both single-SKU and mixed-SKU depalletizing

Single SKU

Multi SKU

High Throughput

Optimized motion paths and cycle planning deliver fast, consistent case-per-minute performance on uniform pallets

Seamless Changeovers

Handles dropped, misaligned, or damaged cases automatically — no stoppages, no operator resets

Compact Integration

Fits easily into existing inbound lines with minimal floor-space impact or workflow disruption

Operator Simplicity

Visual WebUI and guided tools make configuration and monitoring intuitive for every skill level

Vision-Guided Accuracy

3D perception identifies each case precisely, even under shrink-wrap or variable lighting

Proven Reliability

Designed for continuous operation across shifts, with autonomous fault handling and status reporting

Making Robotic Piece Picking a Reality

Unlock intelligent capabilities for both single-SKU and mixed-SKU depalletizing

Single SKU

Multi SKU

High Throughput

Optimized motion paths and cycle planning deliver fast, consistent case-per-minute performance on uniform pallets

Seamless Changeovers

Handles dropped, misaligned, or damaged cases automatically — no stoppages, no operator resets

Compact Integration

Fits easily into existing inbound lines with minimal floor-space impact or workflow disruption

Operator Simplicity

Visual WebUI and guided tools make configuration and monitoring intuitive for every skill level

Vision-Guided Accuracy

3D perception identifies each case precisely, even under shrink-wrap or variable lighting

Proven Reliability

Designed for continuous operation across shifts, with autonomous fault handling and status reporting

Easy setup

Easy setup

See how leading integrators are scaling faster and winning more business with MujinOS. From warehouse logistics to automotive assembly, these deployments show how MujinOS simplifies complex automation—turning one-off projects into repeatable solutions.

See how leading integrators are scaling faster and winning more business with MujinOS. From warehouse logistics to automotive assembly, these deployments show how MujinOS simplifies complex automation—turning one-off projects into repeatable solutions.

Case study

See intelligent robots depalletize at ACME Logistics

MujinOS helped ACME Logistics modernize inbound operations by transforming manual pallet unloading into a fully automated depalletizing system capable of handling mixed, irregular, and wrapped pallets with speed and precision.

Case study

See intelligent robots depalletize at ACME Logistics

MujinOS helped ACME Logistics modernize inbound operations by transforming manual pallet unloading into a fully automated depalletizing system capable of handling mixed, irregular, and wrapped pallets with speed and precision.

Case study

See intelligent robots depalletize at ACME Logistics

MujinOS helped ACME Logistics modernize inbound operations by transforming manual pallet unloading into a fully automated depalletizing system capable of handling mixed, irregular, and wrapped pallets with speed and precision.

Download the MujinOS brochure

Download the MujinOS brochure

This technical guide explains how MujinOS eliminates reprogramming, accelerates changeovers, and delivers consistent high performance across palletizing applications. It’s packed with practical insights for operations leaders, engineers, and integrators evaluating automated palletizing systems.

Have a question?

Learn how MujinOS delivers real-time perception, motion control, and no-code deployment—across any robotic system

Have a question?

Learn how MujinOS delivers real-time perception, motion control, and no-code deployment—across any robotic system

Have a question?

Learn how MujinOS delivers real-time perception, motion control, and no-code deployment—across any robotic system